01 Mechanical engineering

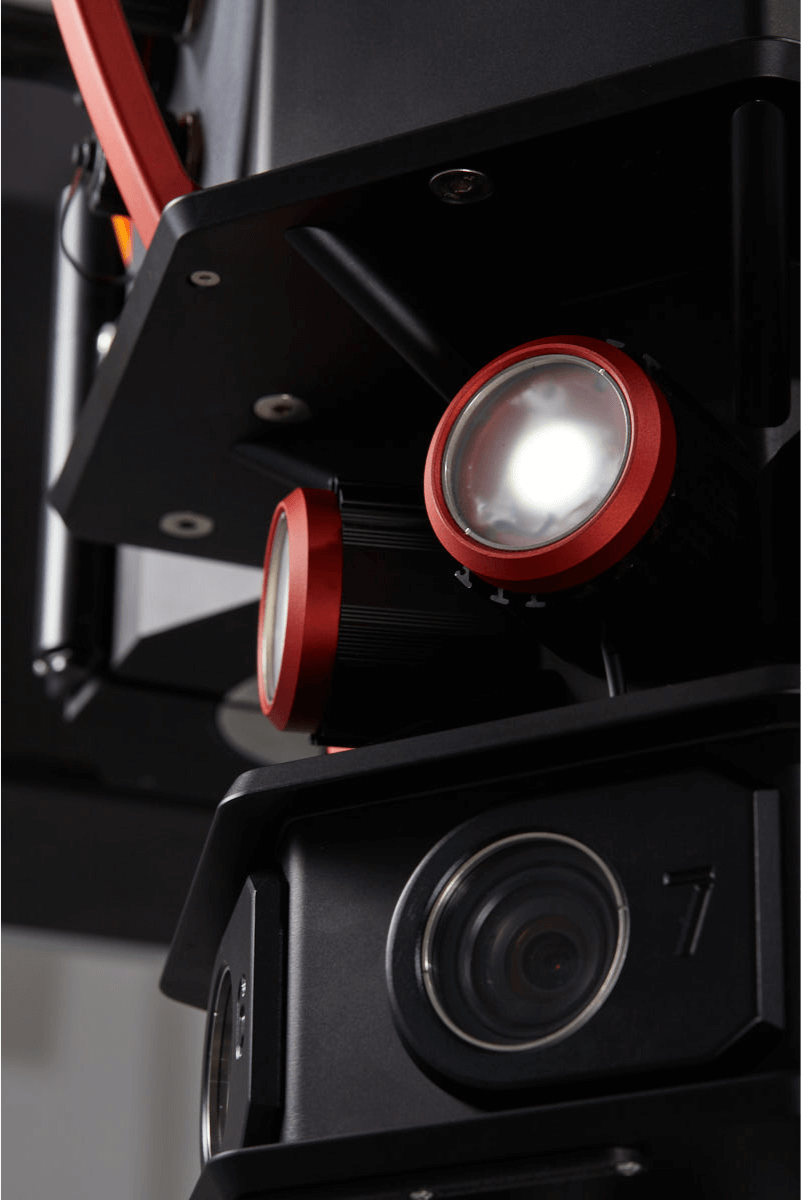

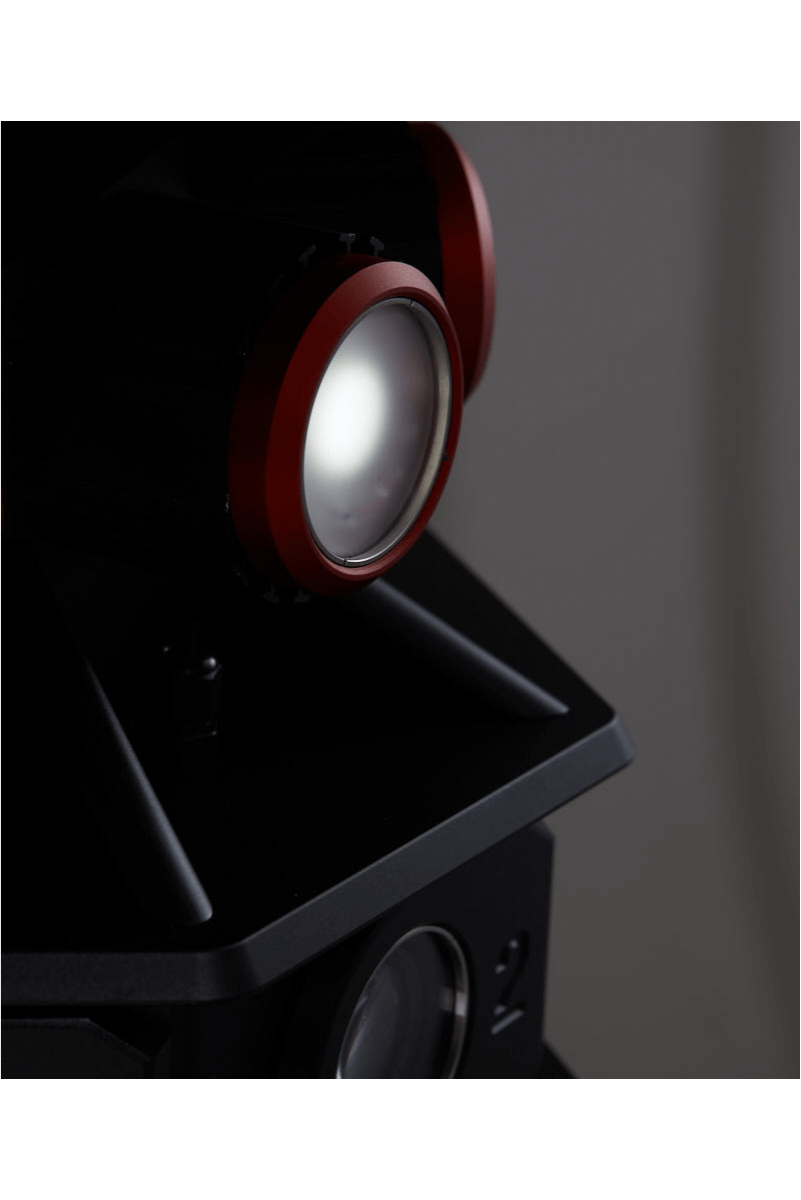

02 Optomechanical design

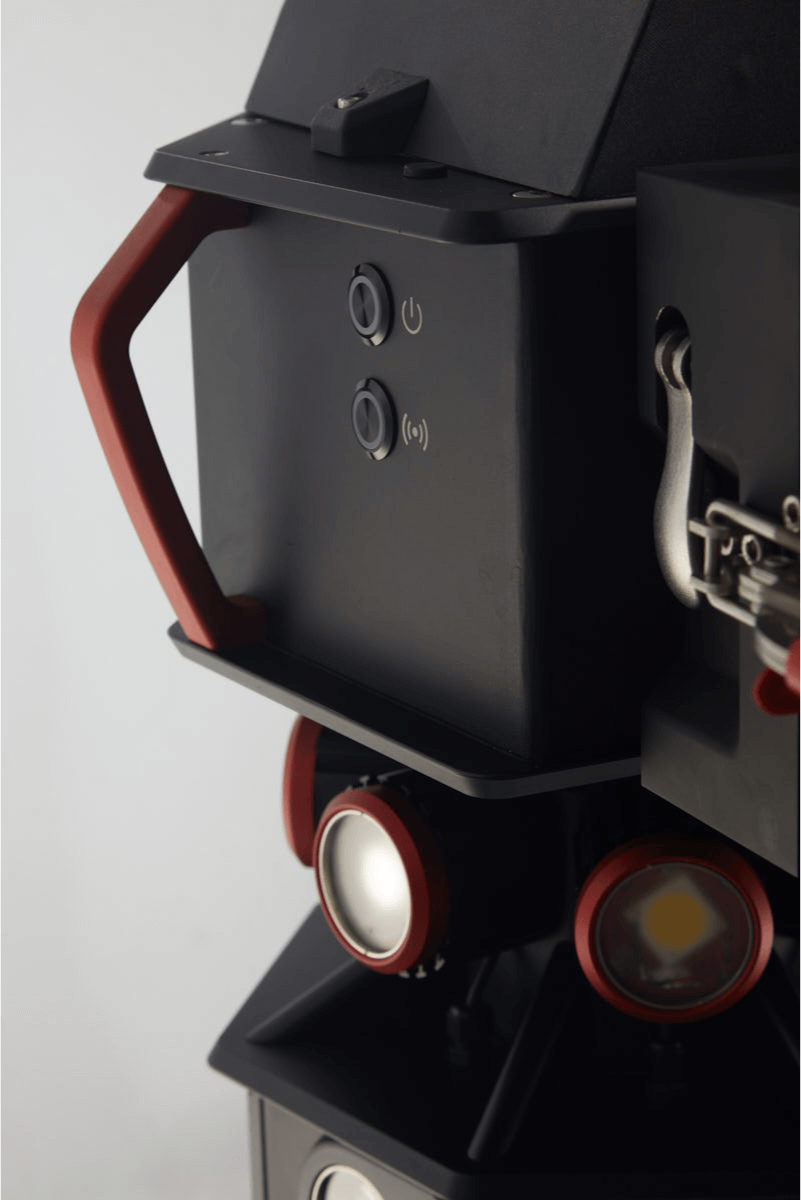

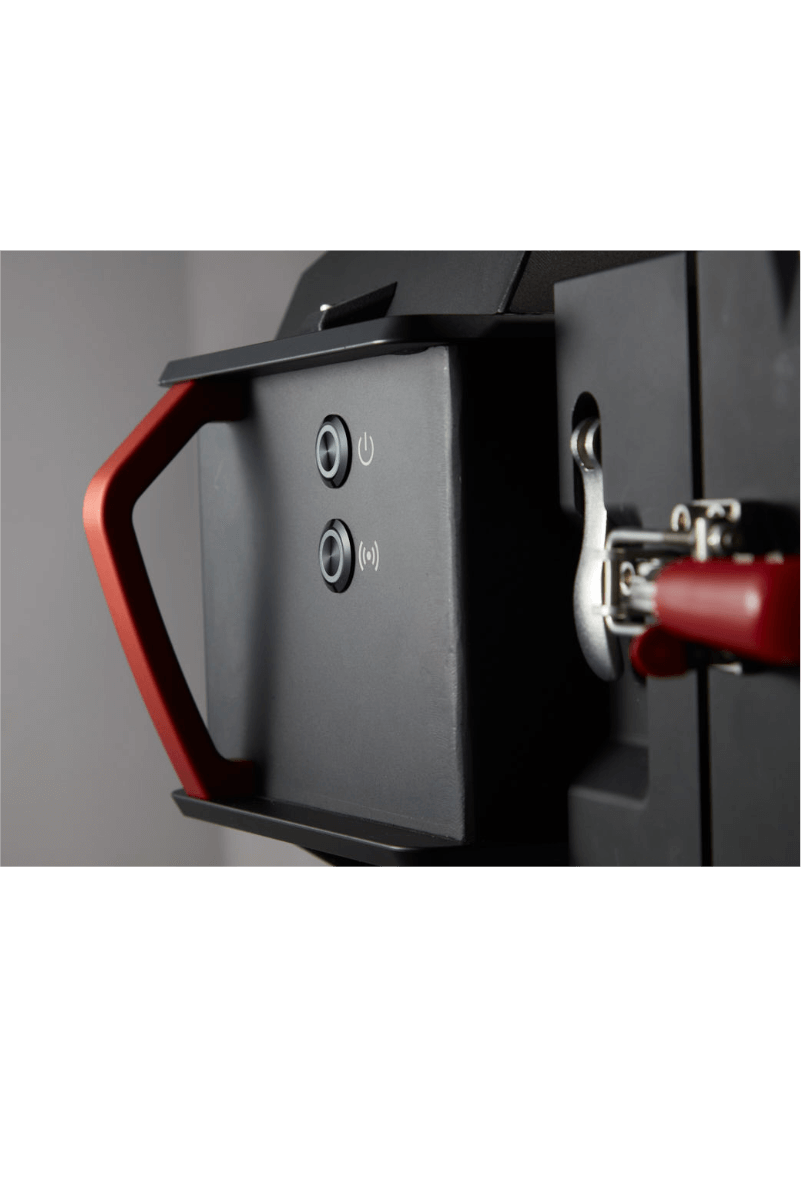

03 Electronic design

04 Waterproofing and robustness

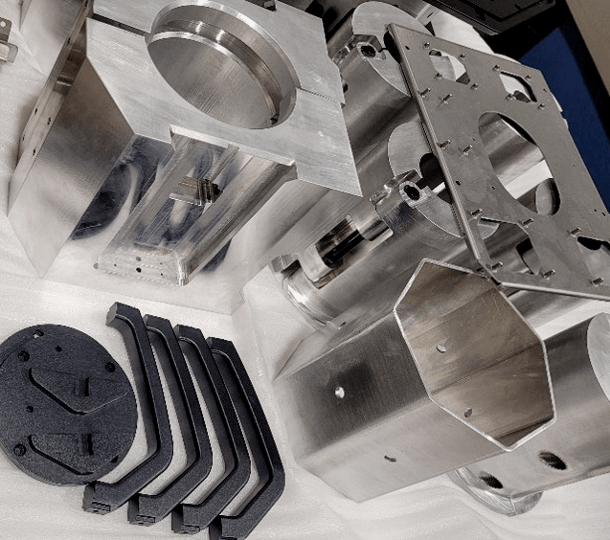

05 Manufacturing

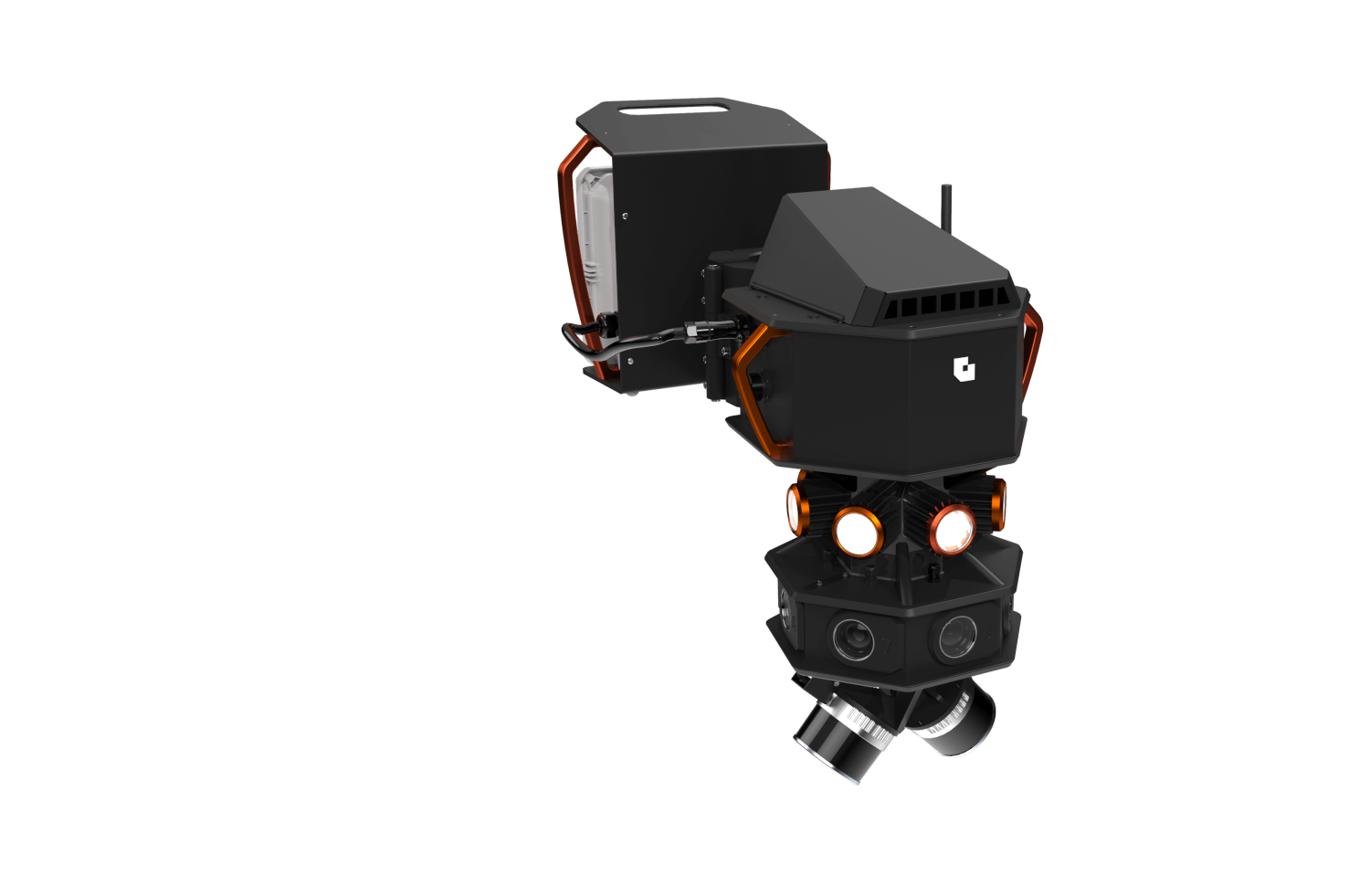

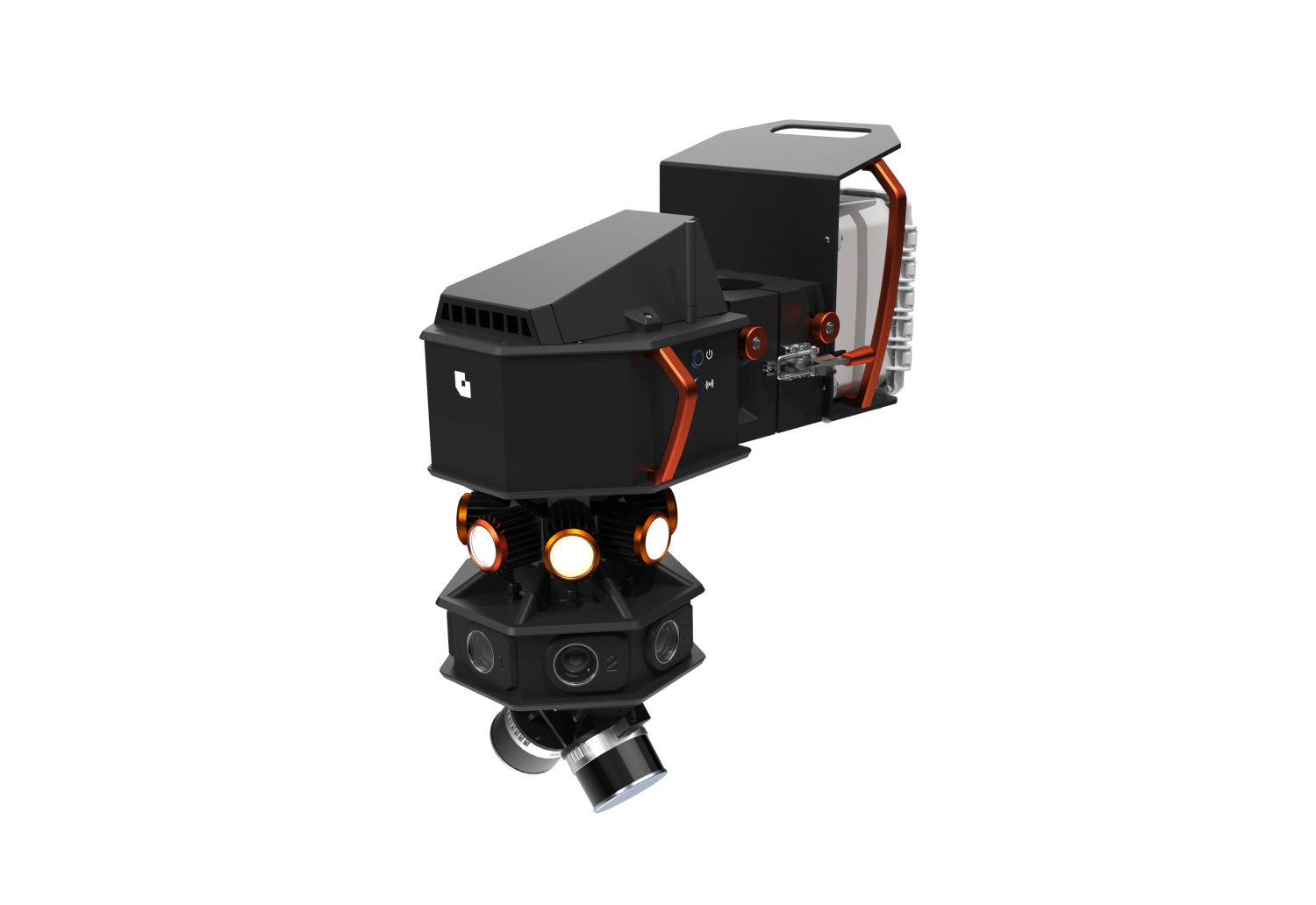

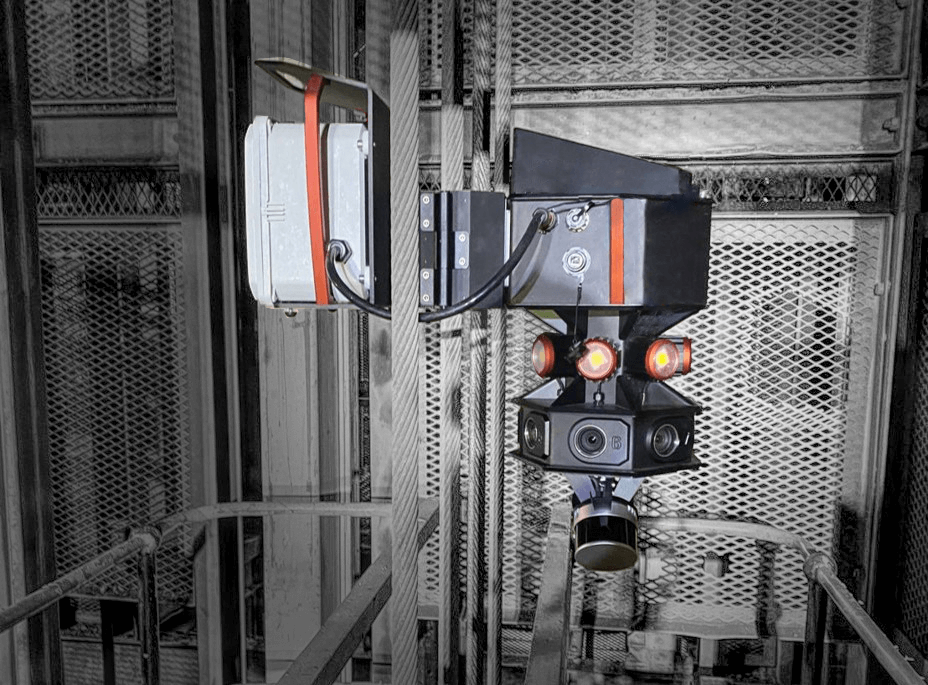

Lazaruss is a solution made possible by Point.LAZ, used to automate the monitoring of mine shafts. A mine shaft is a vertical tunnel-like structure used to extract mineral deposits and typically serves as access points for miners, equipment, and materials necessary for mining resources. Lazaruss generates high-precision data enabling predictive maintenance for these shafts. The product is the result of in-depth research by the Point.LAZ team and a fruitful collaboration with Innovation M2 in the development and manufacturing of this solution.

Discover Point.LAZA process of exploration and validation preceding the development phase

Technological watch &

Industrial Design

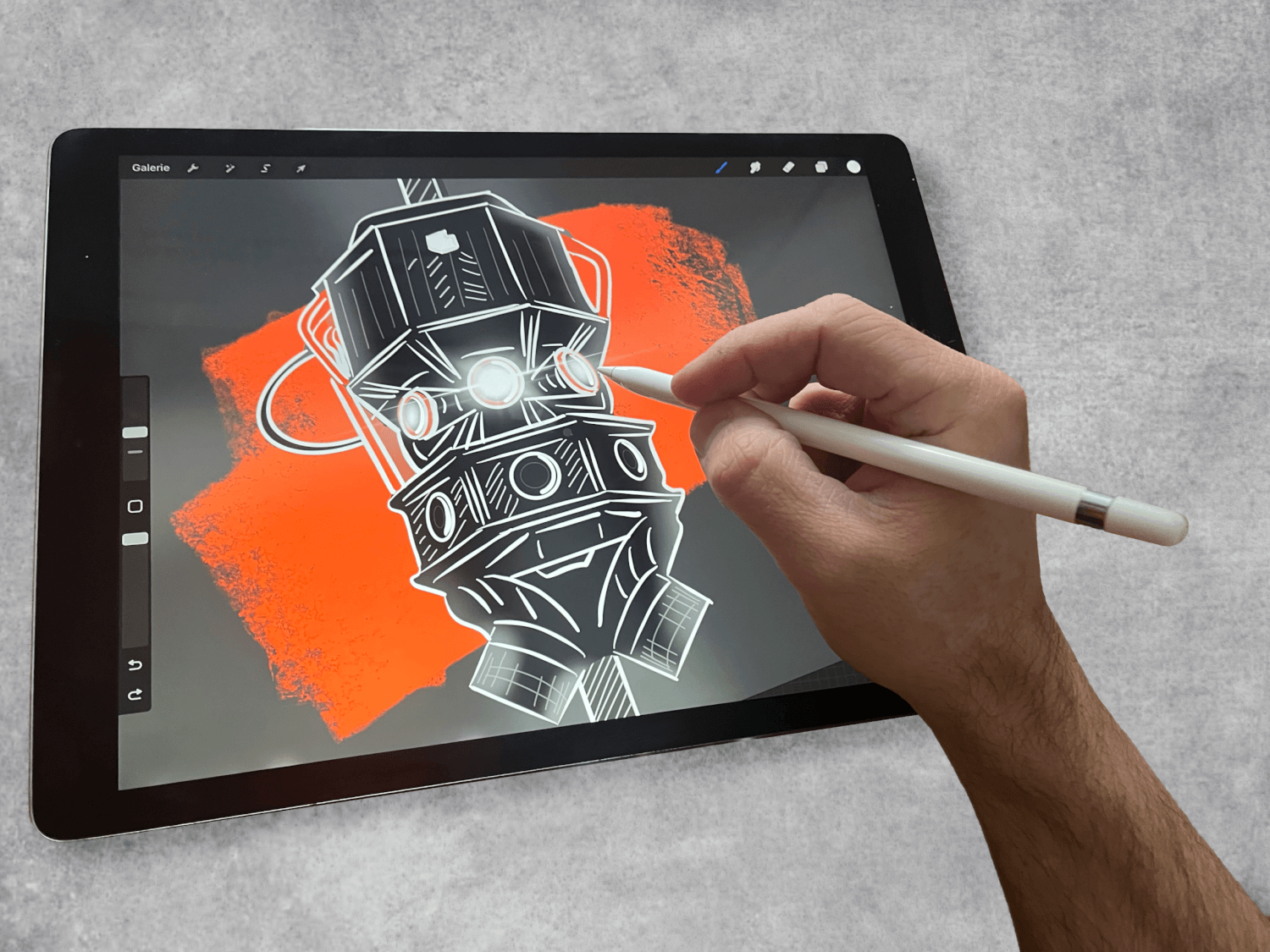

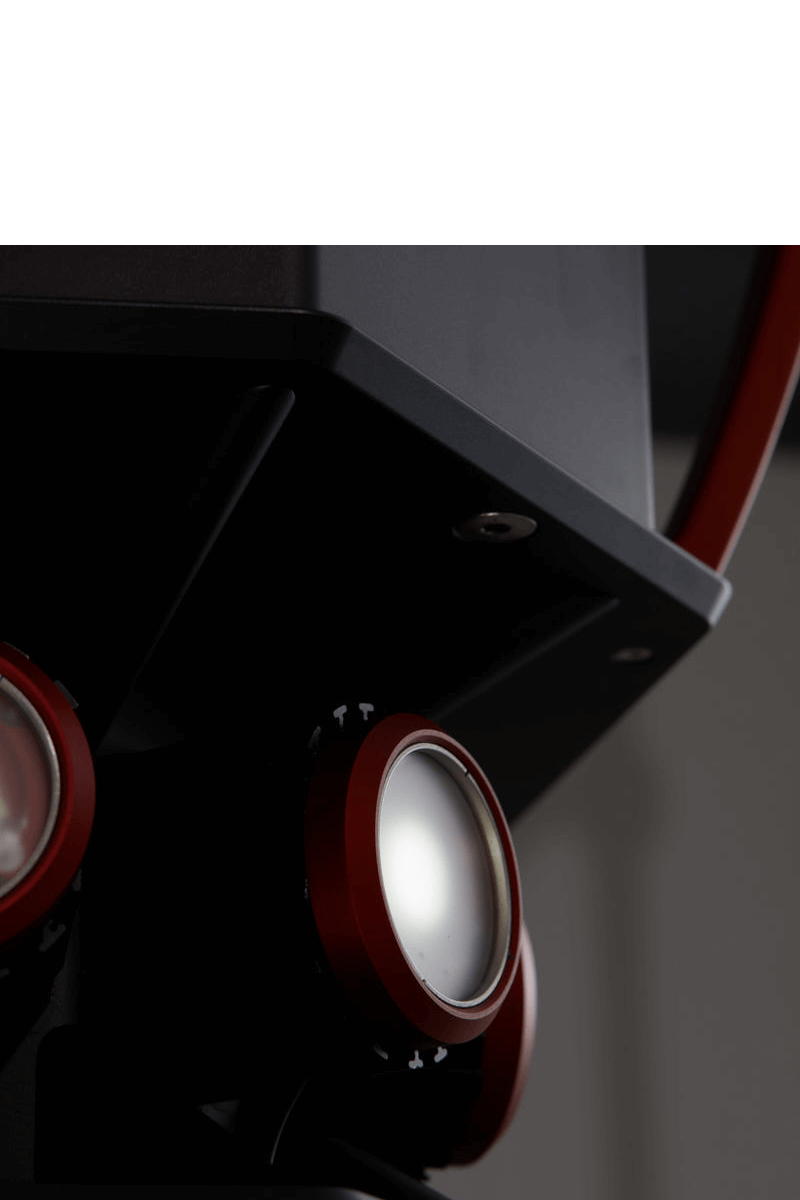

A tech watch serves to understand design trends across various domains and to explore possibilities linked to future conception. This design activity, conducted in partnership with Nicolas Lebrun, delved into shapes, textures, colors, materials, and processes. The exploration extended to products of all kinds to unearth intriguing elements. This tech watch guided the artistic directions of industrial design as a whole. The creative design process is iterative, allowing convergence towards the guiding principles of what the future product will become.

Analyzing each component to ensure the success of the whole

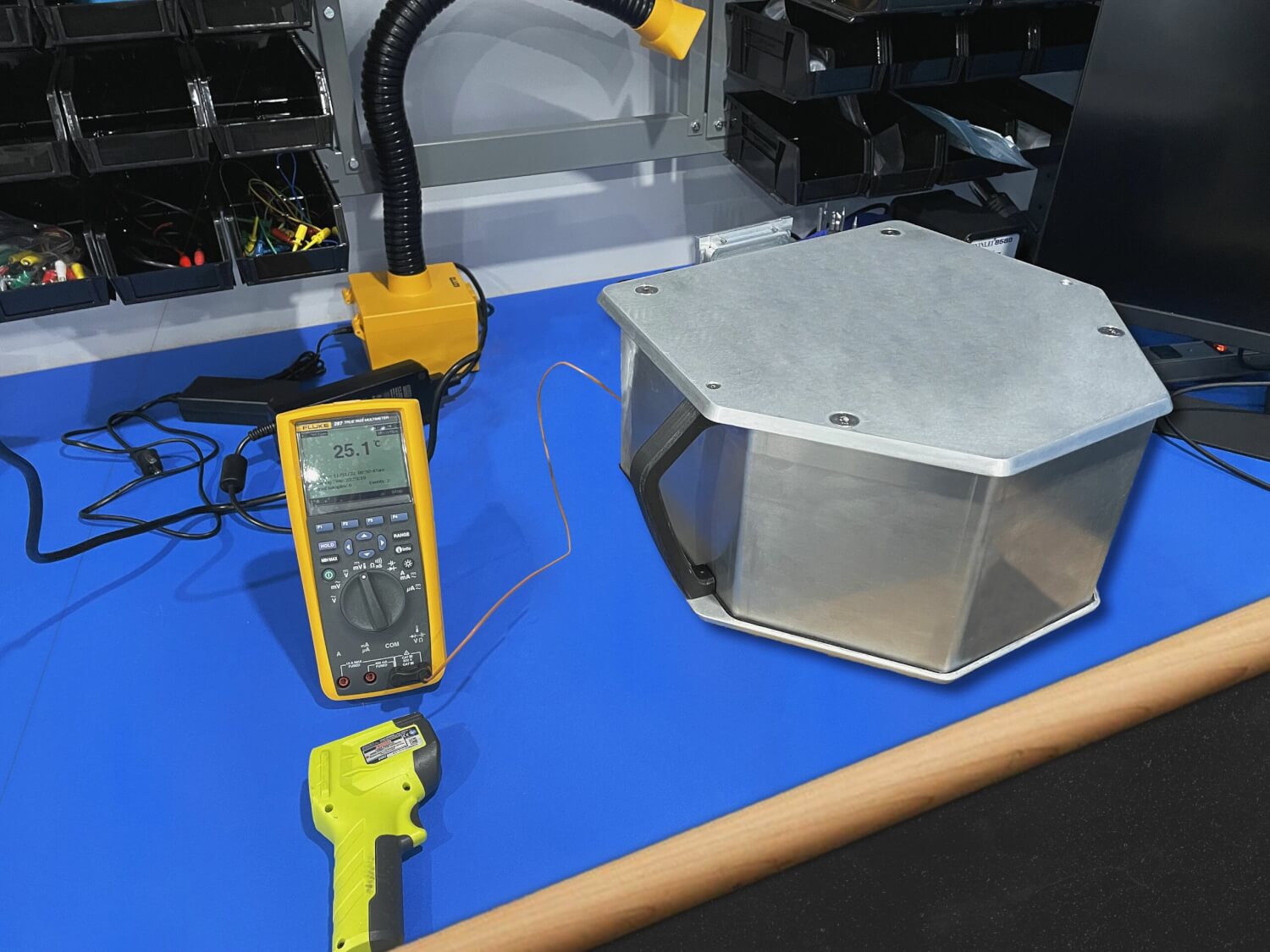

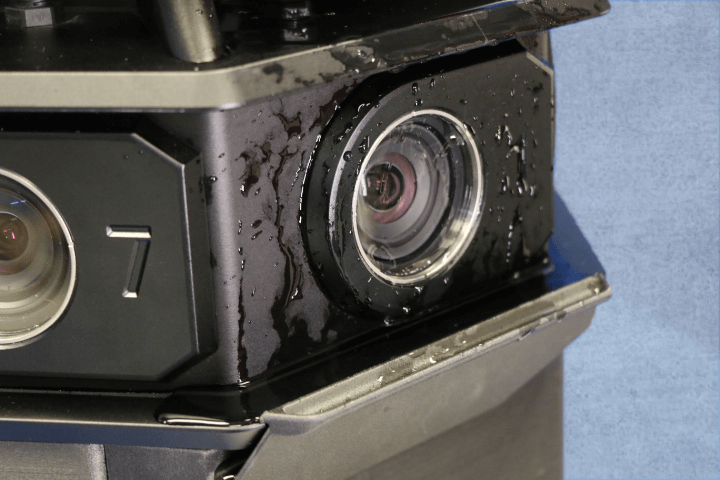

The heat to be dissipated by the casing is considerable; this challenge is accentuated by the need for ingress protection required to withstand a harsh environment. Testing this waterproof subsystem aimed to validate several fundamental hypotheses.

The targeted ingress protection was IP67. The international standard IEC 60529 defines these requirements as follows:

"The first figure defines protection in the face of solid body penetrations. The 6 means that the product is completely protected against dust.

The second figure is linked to water. The 7 promises the resistant of the product to a temporary immersion up to 1 meter for 30 minutes. "

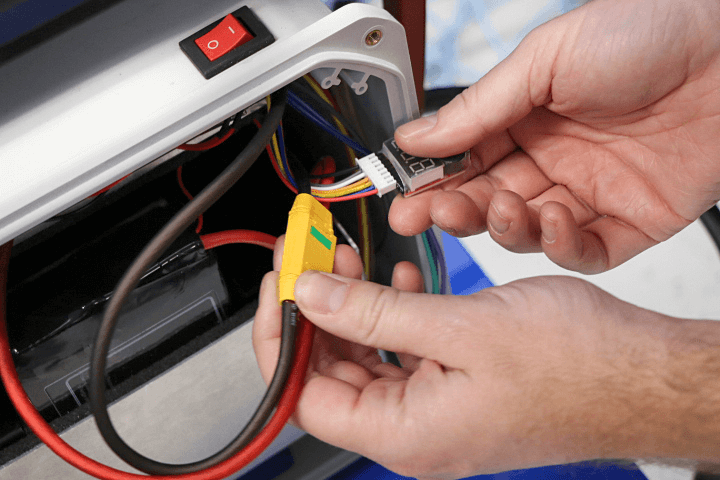

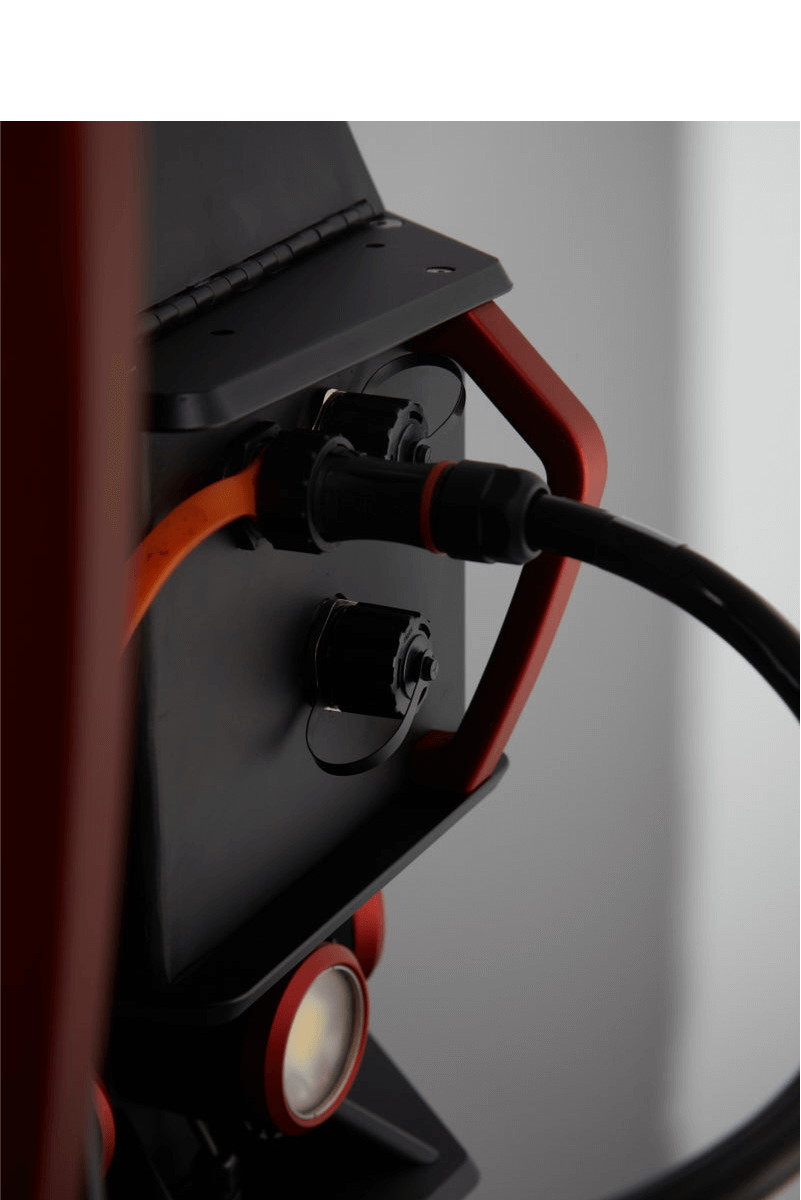

In order to produce an assembly of minimalist battery box, the connector has been greatly simplified

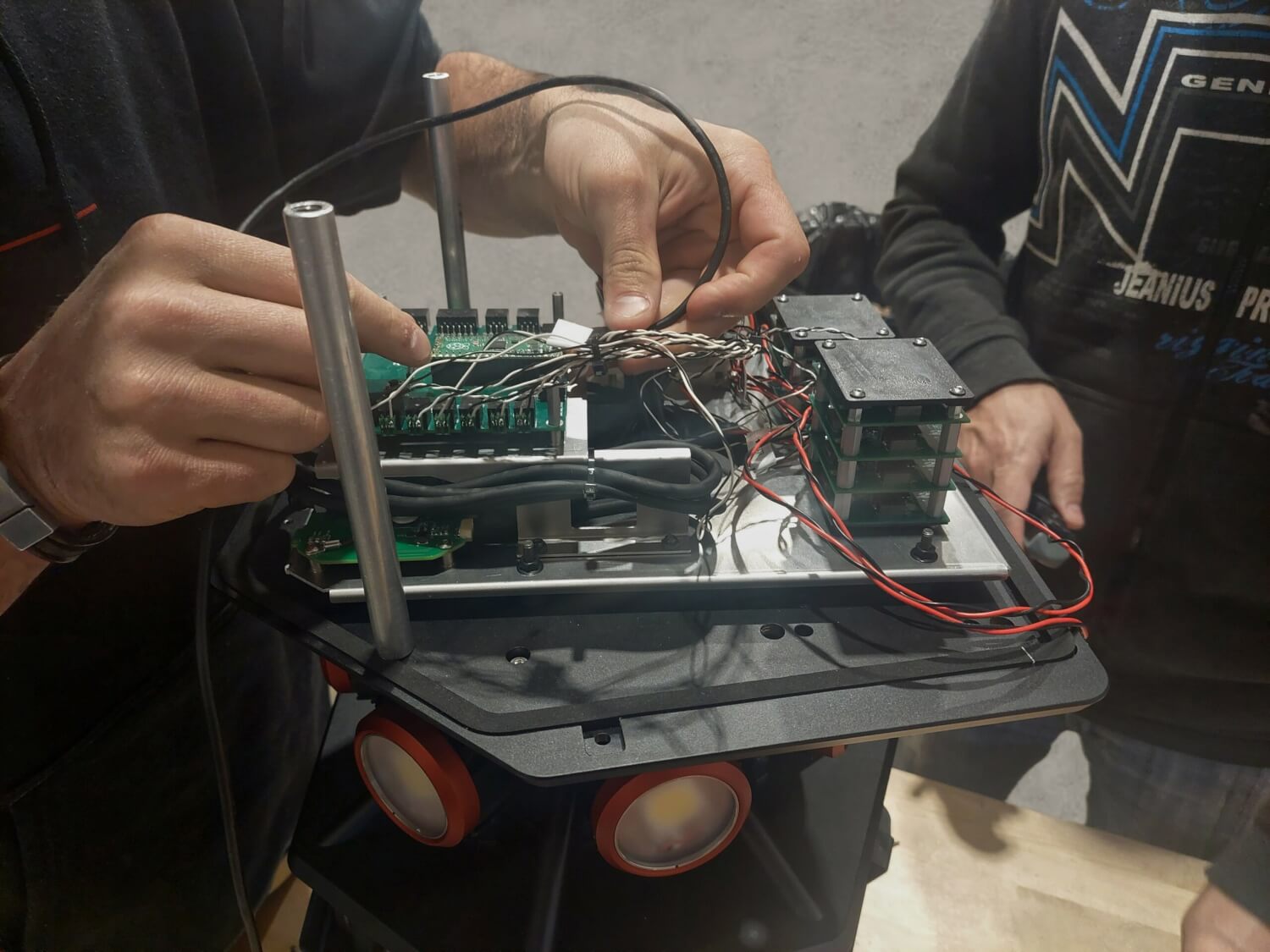

The restricted space was a major issue to consider in design. One of the important validations during prototyping was linked to cable management.

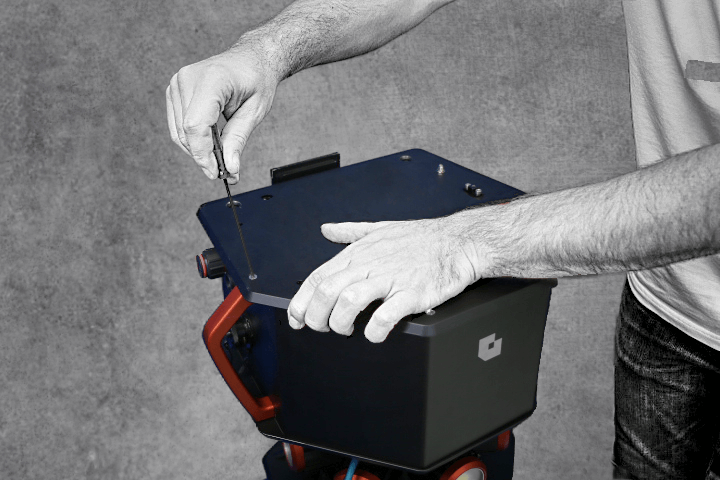

Prototyping was mainly done by Innovation M2: the machining of parts, the supply of the purchased components and the assembly of the units.

The mine is a hostile environment for a technological product. Despite the robustness integrated into the design, the product must be well packaged to allow easy, efficient and safe deployment. The transport case was designed according to this line of thought.

A product designed for a harsh environment

The pilot production units have been tested several times in real situations in Canada as well as in Africa to validate each aspect of the design. The conclusions show a reliable product that meets customer expectations.