A company at the heart

of product development

See our work

Outsourcing

of product

development

& Manufacturing

services

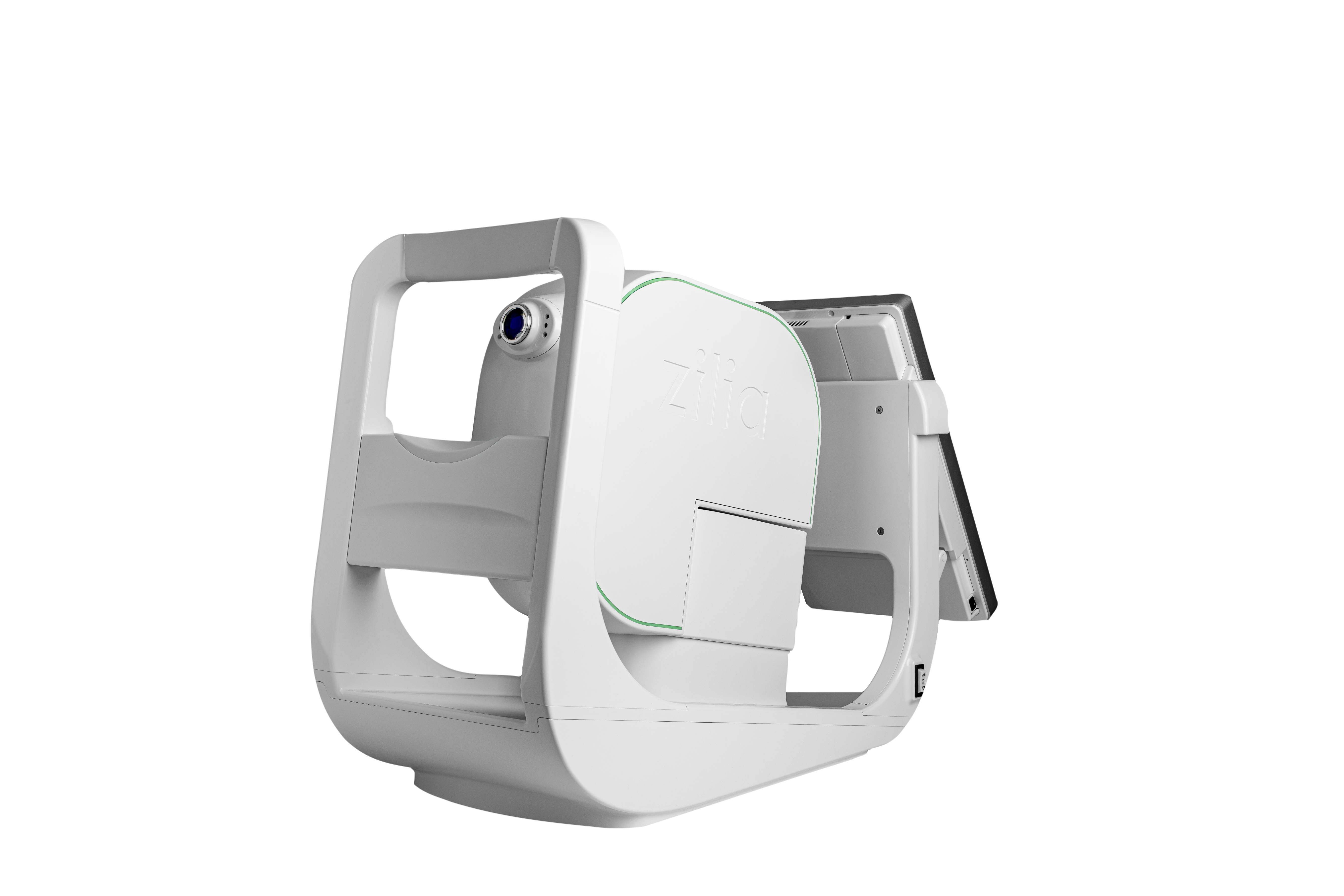

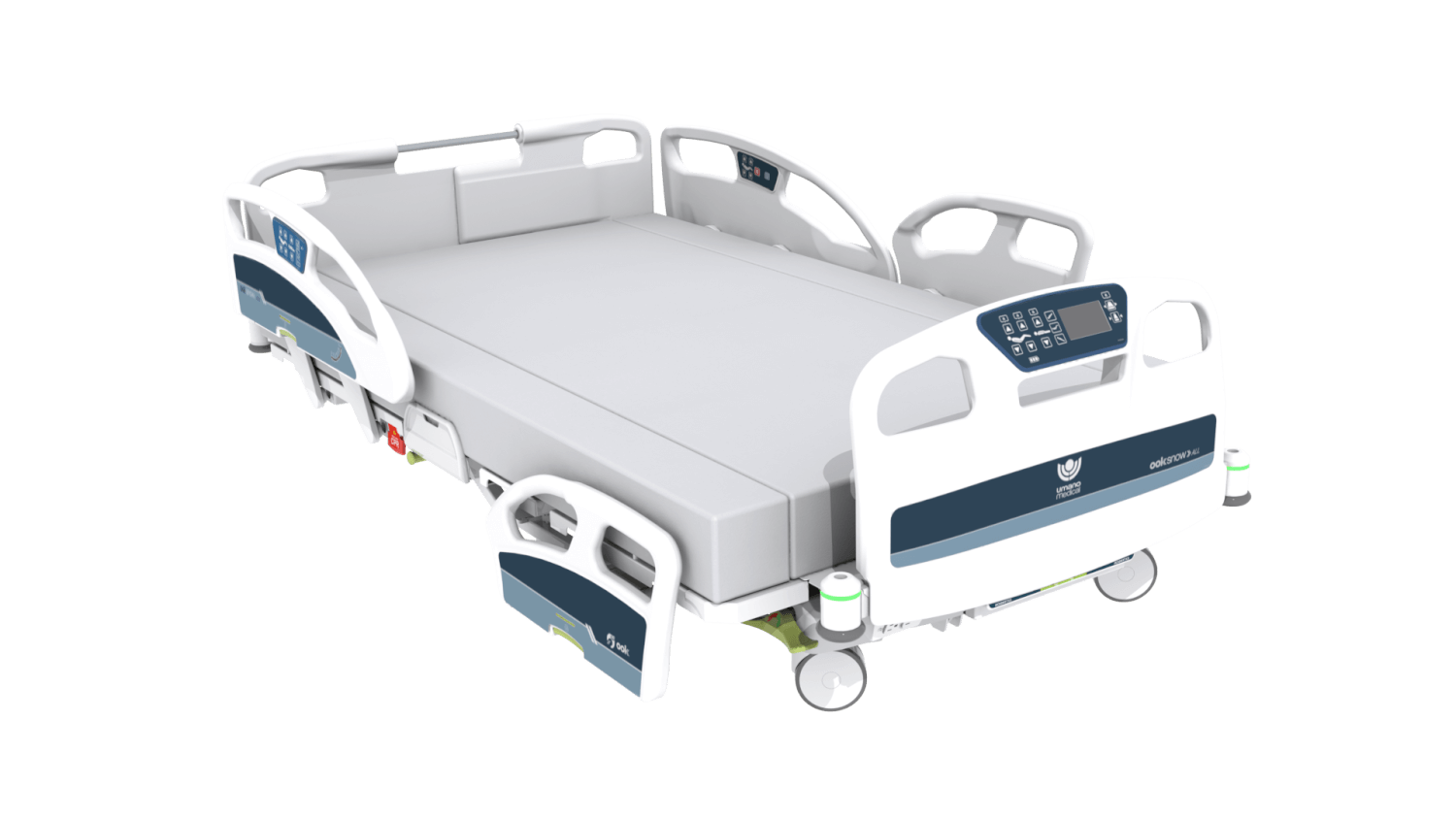

Innovation M2 partners with passionate companies to solve complex challenges and deliver whole and elegant solutions. Working in the fields of healthcare technologies and in industries with high regulatory and technical requirements, Innovation M2 offers multiple services: development of turnkey products, mechanical design, electronic design, firmware programming, industrial design (eligible for credit of tax), simulation, multiple studies and analyzes (human factors, geometric tolerancing, normative analysis, finite elements), tests and validation, prototyping and small batch production.

We regularly work on projects funded through government programs: Industrial Research Assistance Program (IRAP), Marketing and Export Support Program (PSCE), Design Tax Credit, SR&ED tax credits.

Our seasoned team supporting the solutions, made up of engineers, industrial designers, project leaders, and technicians, has enabled the emergence of many medical devices in recent years. Our team is therefore accustomed to working according to the ISO 13845 normative framework (Medical devices — Quality management systems — Requirements for regulatory purposes)

Innovation M2 success is based on its five core values: collaboration, transparency, autonomy, passion, and commitment.

Product development

& Manufacturing services

Mechanical design

See our workShape an idea using multiple techniques such as industrial design, human factors, and engineering

- 01Molded plastic parts (Injection, “Blow molding”, Thermoforming)

- 02Industrial design and CAD models

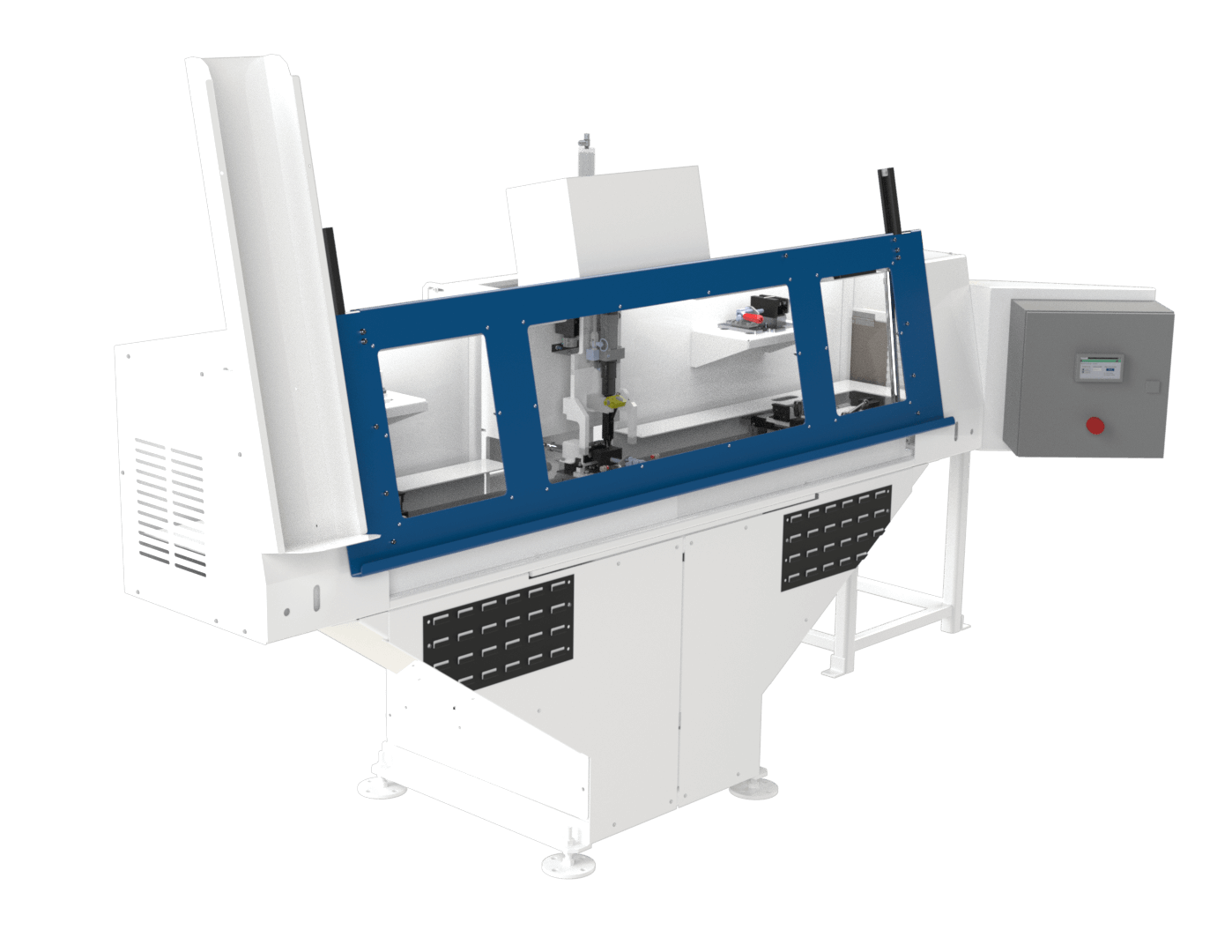

- 03Robotization and systems automation

- 04Design of complex mechanisms

Product development

Electronic design

See our workCarry out a technological product requires great rigor combined with practical experience.

- 01Schematic Layout Design (PCB)

- 02Firmware programming

- 03Prototyping and validation

- 04Support in product certification

Product development

Simulation & Validation

See our workBringing simulation during development helps reduce validation time and cost

- 01Finite element analysis (FEA)

- 02Design, manufacture, and automation of test benches

- 03Development of test protocols

- 04Execution of tests and documentation of results

Product development

Product launch

See our workOur team lightens the complex and essential tasks during the new product introduction

- 01Rendering & manual writing

- 02Manufacturing & assembly plans

- 03Manufacture of test benches

- 04Pre-certification validations

Manufacturing services

Manufacturing & Production

See our workOutsource an accessory or the manufacture of a prototype in order to stay focused on production; Focus on sales and customer needs without worrying about production challenges

- 01Low-volume production

- 02Prototyping of parts and assembly

- 03Assembly of subsystems

- 04Quality management (ISO 13485 implementation in progress)

Manufacturing services

Optimization

See our workOnce the product is in production, R&D must focus on the future and production, on day-to-day issues, Innovation M2 can optimize the products in production by respecting rigorous Engineering changes.

- 01Product improvement

- 02Cost reduction by systems simplification

- 03Cost reduction by process analysis

- 04Manufacturer transfer

Manufacturing services

Mechanical design

Shape an idea using multiple techniques such as industrial design, human factors, and engineering

- 01Molded plastic parts (Injection, “Blow molding”, Thermoforming)

- 02Industrial design and CAD models

- 03Robotization and systems automation

- 04Design of complex mechanisms

Product development

Electronic design

Carry out a technological product requires great rigor combined with practical experience.

- 01Schematic Layout Design (PCB)

- 02Firmware programming

- 03Prototyping and validation

- 04Support in product certification

Product development

Simulation & Validation

Bringing simulation during development helps reduce validation time and cost

- 01Finite element analysis (FEA)

- 02Design, manufacture, and automation of test benches

- 03Development of test protocols

- 04Execution of tests and documentation of results

Product development

Product launch

Our team lightens the complex and essential tasks during the new product introduction

- 01Rendering & manual writing

- 02Manufacturing & assembly plans

- 03Manufacture of test benches

- 04Pre-certification validations

Manufacturing services

Manufacturing & Production

Outsource an accessory or the manufacture of a prototype in order to stay focused on production; Focus on sales and customer needs without worrying about production challenges

- 01Low-volume production

- 02Prototyping of parts and assembly

- 03Assembly of subsystems

- 04Quality management (ISO 13485 implementation in progress)

Manufacturing services

Optimization

Once the product is in production, R&D must focus on the future and production, on day-to-day issues, Innovation M2 can optimize the products in production by respecting rigorous Engineering changes.

- 01Product improvement

- 02Cost reduction by systems simplification

- 03Cost reduction by process analysis

- 04Manufacturer transfer

Manufacturing services

The whole is greater

than the sum of its parts

— Fervent of product development, LP divides his time between business and design

Business development

Louis-Philippe Dion, P.Eng.

— As a cornerstone, Marco's focus is to elevate each partner to see them flourish

President & Senior designer

Marco Morin

— Sylvain is at the heart of the development of medical products for over 15 years

Director of engineering

Sylvain Lacasse, P.Eng.

— With 20 years of diverse experience, Frederic is an excellent versatile designer

Project leader

Frédéric Renaud

— His ingenuity and talent combine perfectly with his passion for mechanical design

Project leader

David Gagnon, P.Eng.

— Expert in manufacturing processes, Luc is knowledgeable about various medical products

Project leader

Luc Petitpas

— His remarkable analytical mind strengthens his expertise in structural studies

Mechanical designer

Thomas Grégoire, CEP

— Miguel is driven by the search and delivery of concrete solutions and prototyping

Mechanical designer

Miguel Fortin, CEP

— Bianca delivers human-centric solutions during the transfer to production

CEP manufacturing engineering

Bianca Lachance, CEP

— Antoine specializes in 3-axis machining, 3D printing and low-volume assembly

Production technician

Antoine Guay

— Frédéric is dedicated to the prototyping of parts and assemblies including welding

Prototyping specialist

Fredéric Ouellet

— Since 2010, Mikhael has developed lots of electronics devices. He specializes in PCB design & Firmware programming

Electronic coordonator

Mikhael Côté, P.Eng.

— Sharp and pragmatic, William is focused on delivering simple and elegant solutions

Mechanical designer

William Tremblay, CEP

— Raphael accumulates a varied experience including the use of traditional processes

Mechanical designer

Raphael Turcotte, CEP

— Guillaume deploys amazing solutions through his exemplary work ethic and cleverness

Mechanical engineer

Guillaume Boulianne, P.Eng.

— Mathieu specializes in electronic design, PCB and firmware

Electronic designer

Mathieu Mercier, P.Eng.

— Sarah-Kim is driven by helping others and feeling that she can make a difference

Project leader

Sarah-Kim Pelletier, P.Eng.

— Organized and autonomous, each mission entrusted to Marco is accomplished efficiently

Mechanical designer

Marco Roger, CEP

— Olivier combines the arts with technology to create something beautiful and tangible

Industrial designer

Olivier Bujold

— Sharp and pragmatic, Patrick is focused on delivering simple and elegant solutions

Mechanical designer

Patrick Grenier

— Mathieu enjoys listening and understanding to deliver an artistic and innovative result

Industrial designer

Mathieu St-Amant

— Antoine deploys amazing solutions through his exemplary work ethic and cleverness

Electronic designer

Antoine Levesque

— His passion for engineering translates into surpassed expectations of our customers

Mechanical designer

Antony Constant, CEP

— Josette, armed with exemplary rigor, manages larger volume technical assemblies

Technical assembler

Josette Lapierre

— Focus and optimizer, Simon directs our operations (manufacturing and assembly)

Director of operations

Simon Cloutier

Blog

-

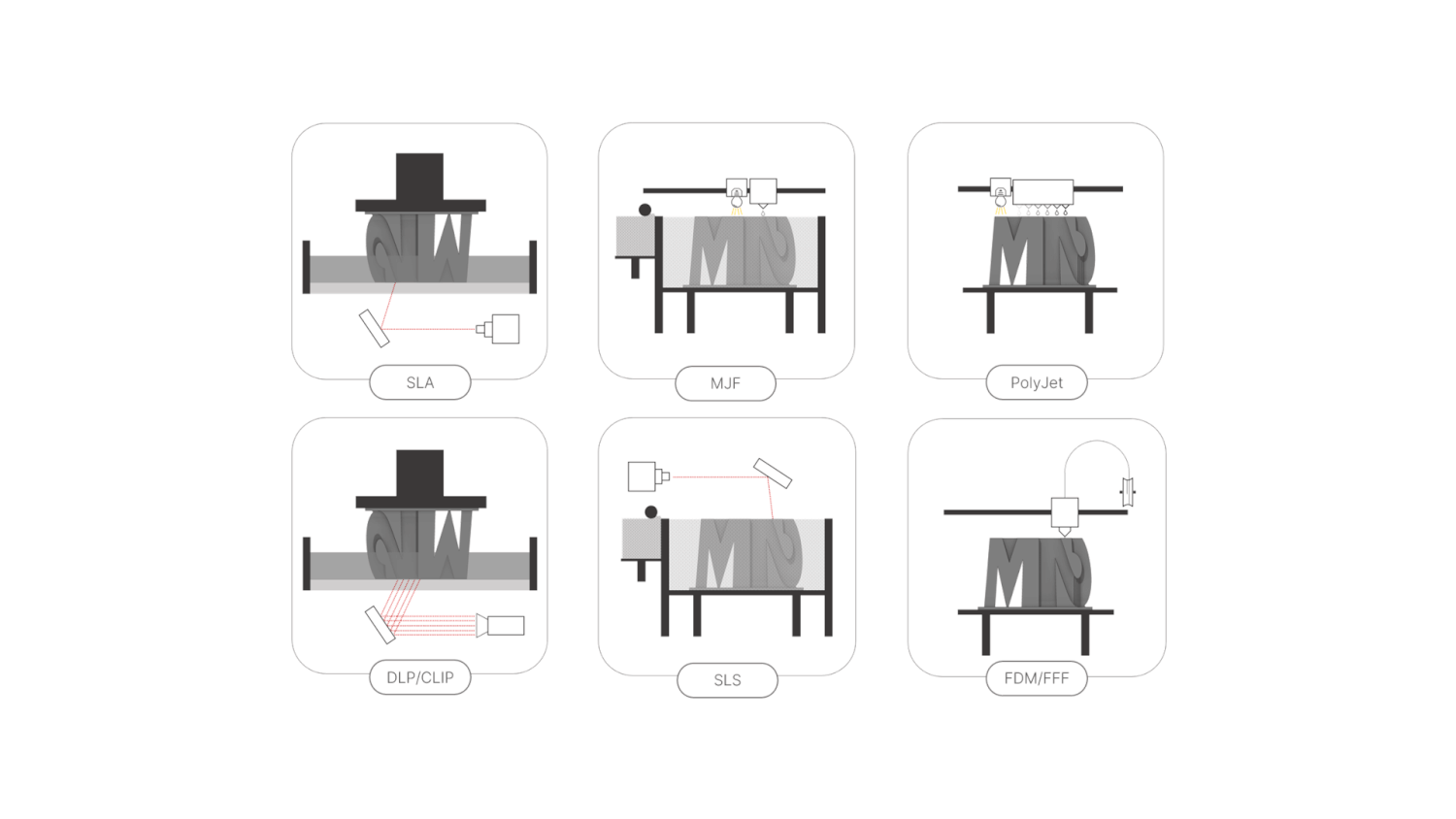

3D Printing - Variety of processes

There are a good number of 3D printing technologies available on the market. Understanding their working principles and discerning their differences allows you to choose the right process according to the needs of the application.

2023Expertise -

3D Printing - FDM - Design Guidelines

At first glance, fused deposition modeling printing (FDM) seems quite simple. Indeed, almost all geometries can be manufactured by FDM. However, it is possible to optimize the design of a part in order to have a good finish, to avoid "post-processing" and to keep a desired geometry.

2023Expertise -

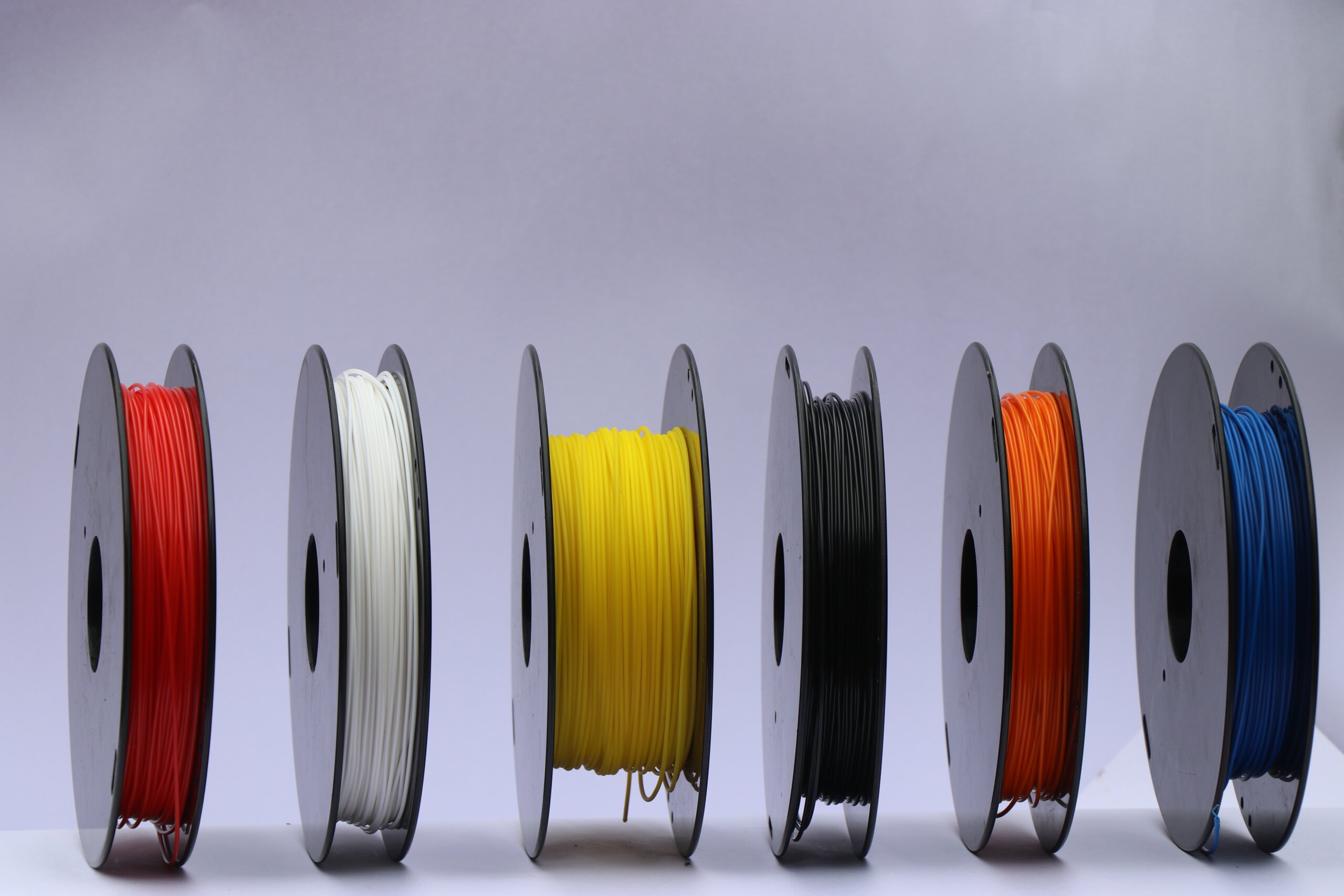

3D Printing - FDM - Filament Choice

Since the launch of the first 3D printer by Stratasys, only offering, at the time, ABS as a printing material, the plastic filament market has grown to now offer dozens of different materials. This expanded offering gives many opportunities and each filament can have its advantages and downsides depending on the purpose of the produced part. This article presents some filaments and their characteristics.

2023Expertise -

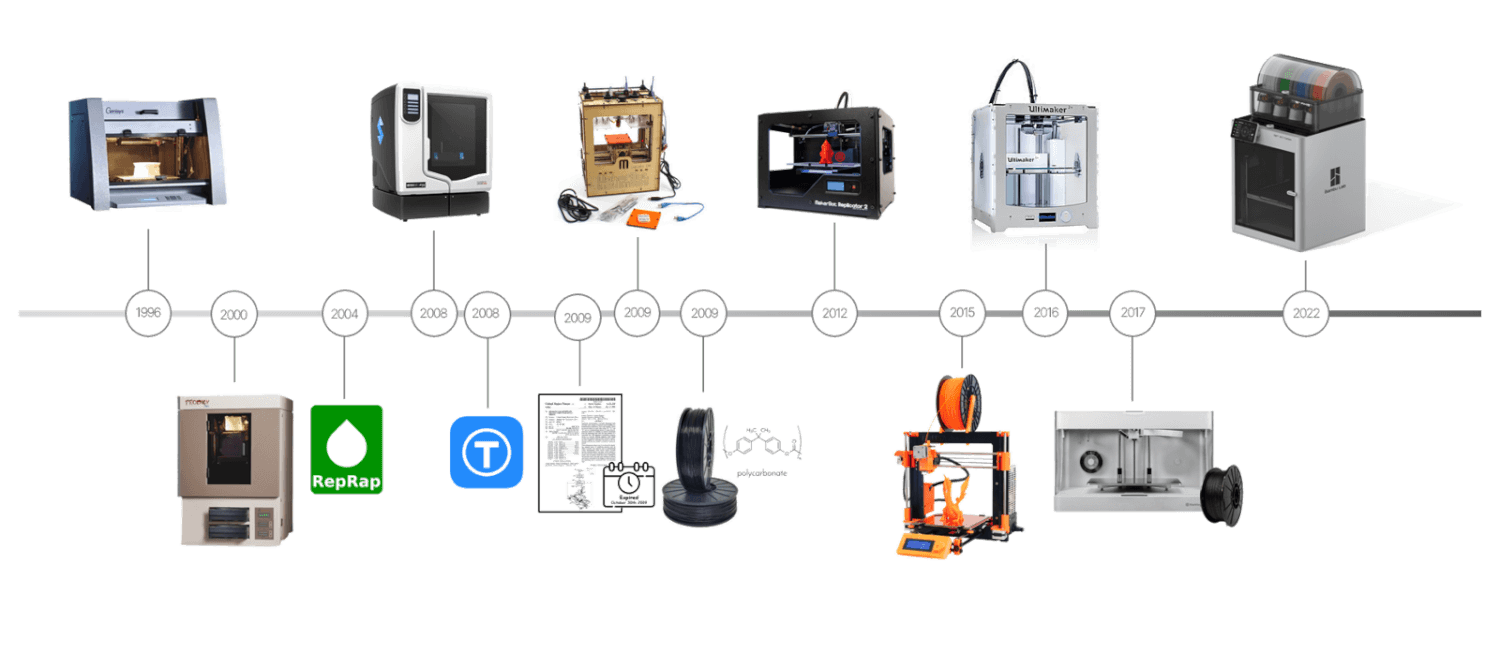

3D Printing - FDM - Desktop Printer

Fused deposition modeling, better known by the acronym FDM, is the most recognized additive manufacturing process. This "bit of history" blog post highlights the evolution of the desktop 3D printer in corporate engineering offices. We therefore focus on machines with a smaller form factor and on innovations making it possible to reduce acquisition cost.

2023Expertise