01 Industrial design

02 Mechanical engineering

03 Electronic design

04 Tests & Validation

05 Manufacturing

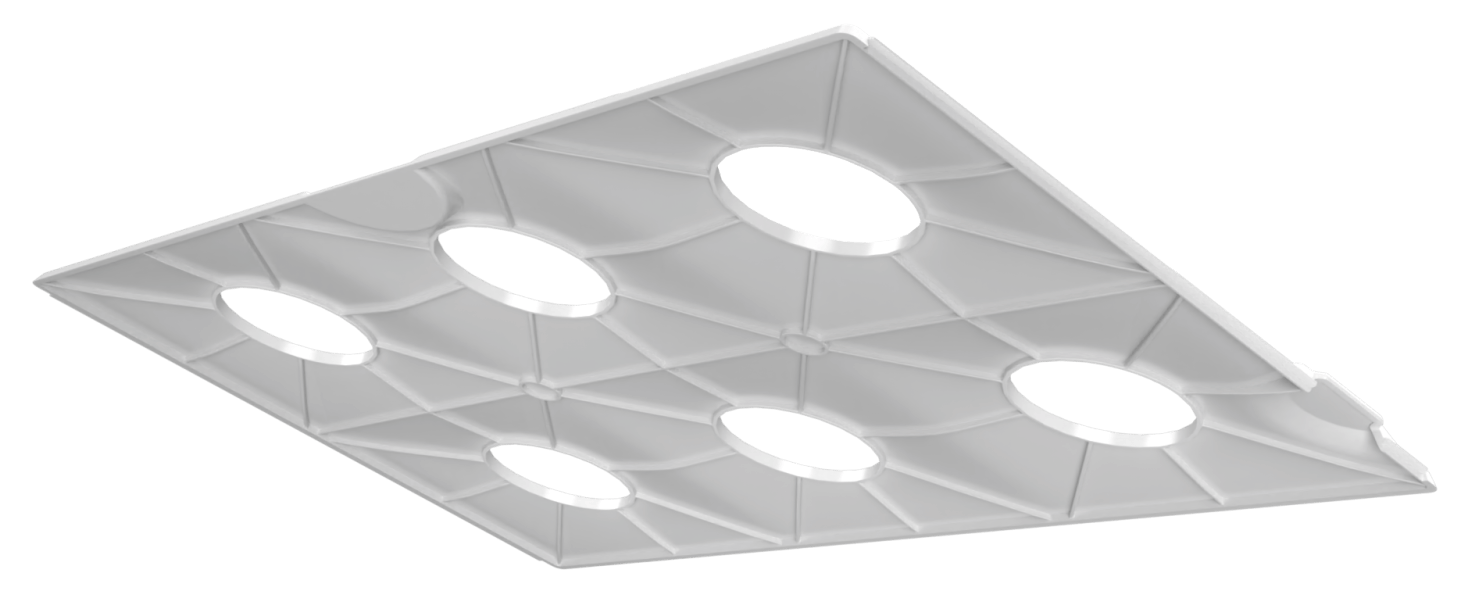

Vireo offers a turnkey hydroponic garden project specifically designed for classrooms. This comprehensive system includes a robust physical product, an intuitive educational dashboard, and high-quality technical support.

Innovation M2 played a key role in the development of this hydroponic garden, aiming for a reliable, elegant design optimized to provide a reasonable production cost. The design was made with consideration for all users involved, whether students, teachers, or support teams, at every stage of the product's lifecycle: from receiving the garden and setting it up on the first day to storing it at the end of the school year.

This collaboration in product development has evolved into a lasting partnership for the production of the units, a cooperation that remains active to this day.

Vireo provides "a nurturing and transformative educational experience that empowers students to reach their full academic and personal potential."

The philosophy behind the design of the hydroponic garden is based on a harmonious integration into the classroom environment. The product is designed to be user-friendly for the teacher, attractive to the students, engaging when focused on, and discreet when regular classroom activities continue.

Design

An experienced team to deliver exceptional results

The product's specifications were particularly demanding, aiming to create a high-end product that stands out in a highly competitive market. The key to achieving the expected result lies in a design team with many years of experience. To achieve this, Innovation M2 relies on two fundamental pillars: recruiting highly skilled personnel and an effective talent retention strategy.

Vireo and Innovation M2 work together with the goal of: "Contributing to the positive transformative experience of classrooms in Quebec and across North America."

Cost Analysis

The key components with potential cost reduction were identified. The design team developed several variants based on different manufacturing processes, thus providing opportunities for cost reduction while maintaining the product's quality.

The quantity of parts produced per year is the first factor to consider.

If the quantities are sufficient, a high tooling cost is amortized over a large volume of parts, resulting in a low manufacturing cost.

Choice of process /

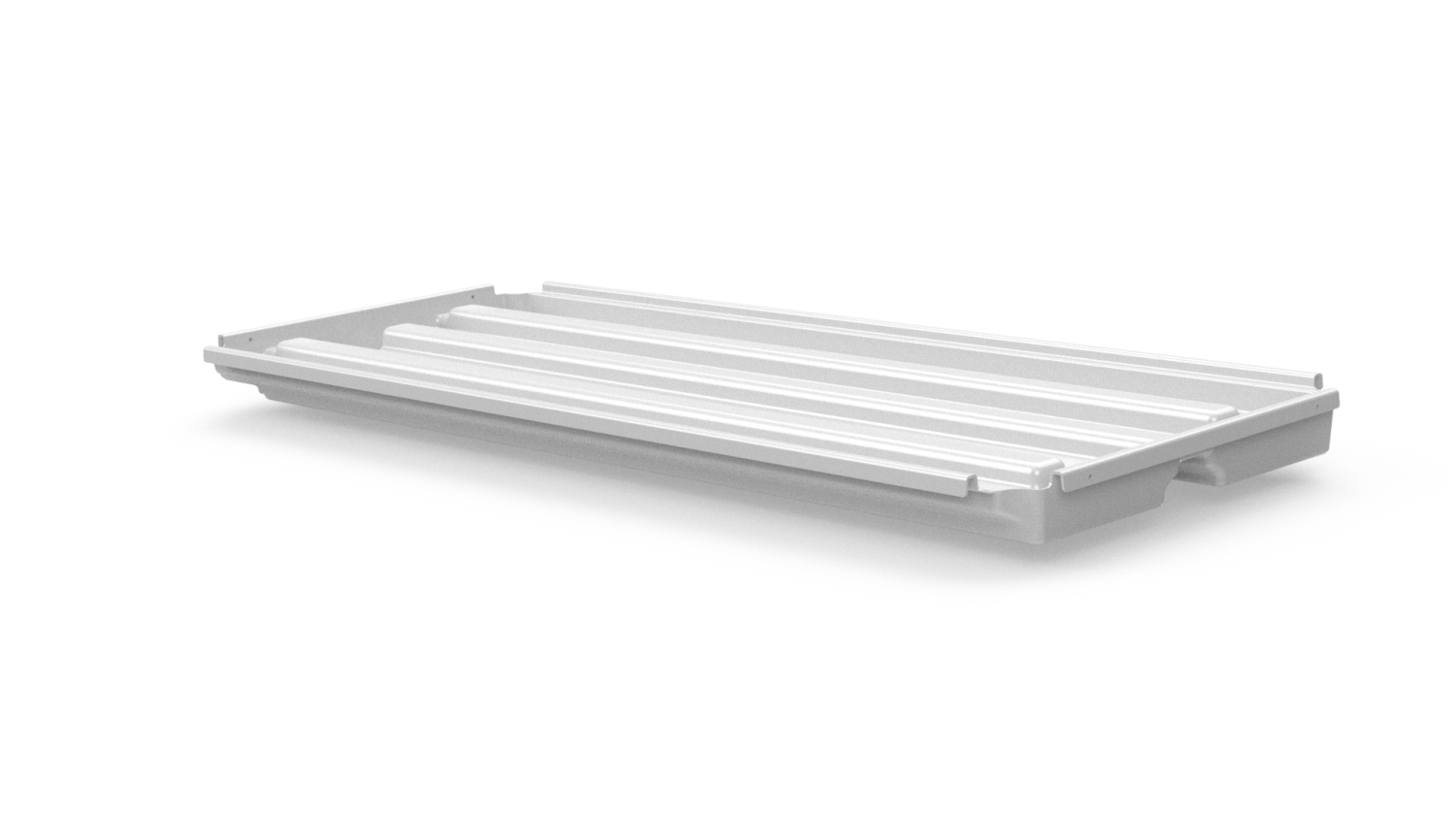

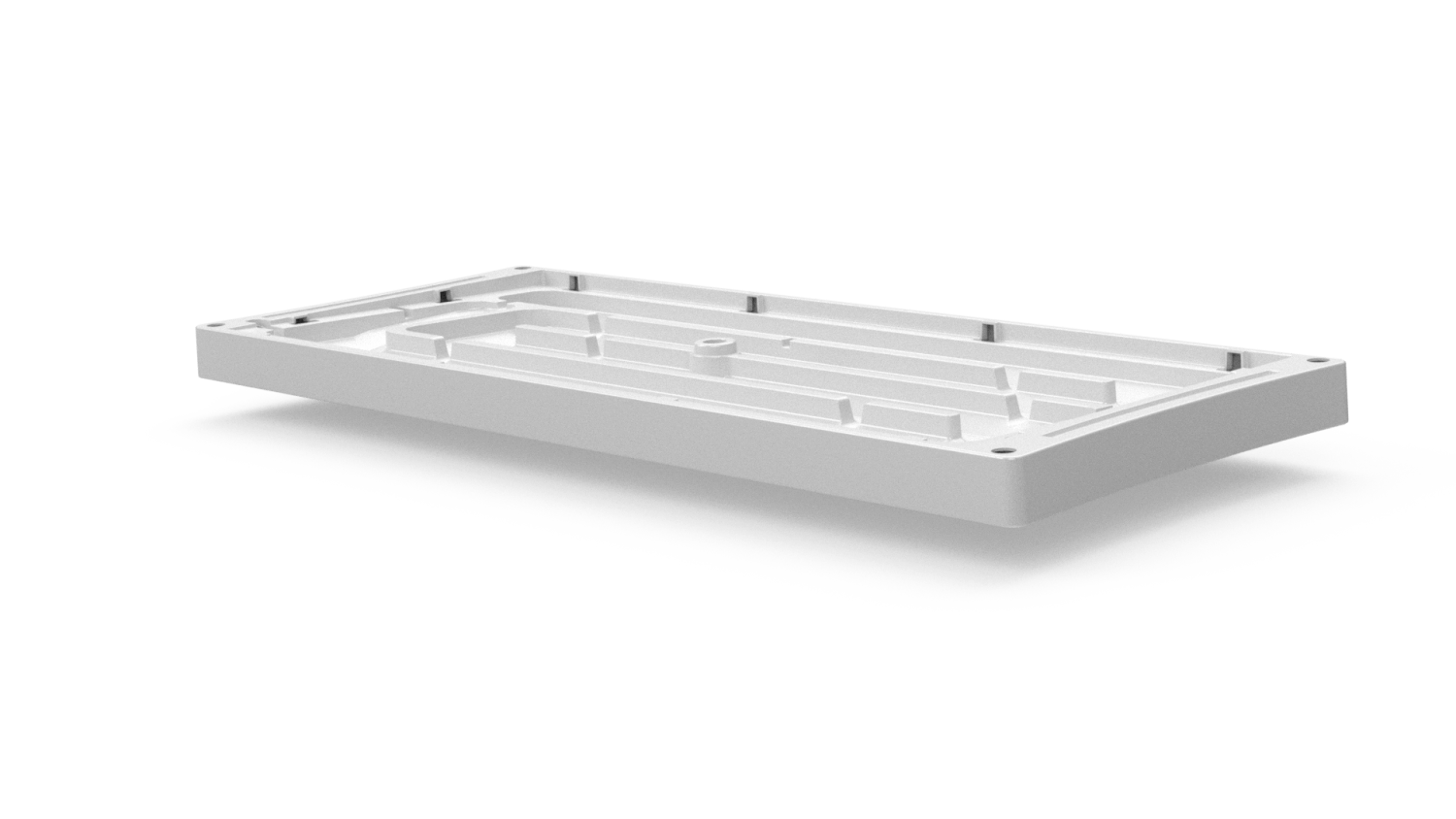

Garden trays

Thermoforming was compared to rotational molding in a thorough analysis aimed at ensuring the best quality/price ratio. After careful evaluation, the rotational molded part was selected for this project.

Thermoformed part with a lower tray made of folded sheet metal

Complete rotational molded part

"Success depends on how we use the right tools at the right time."

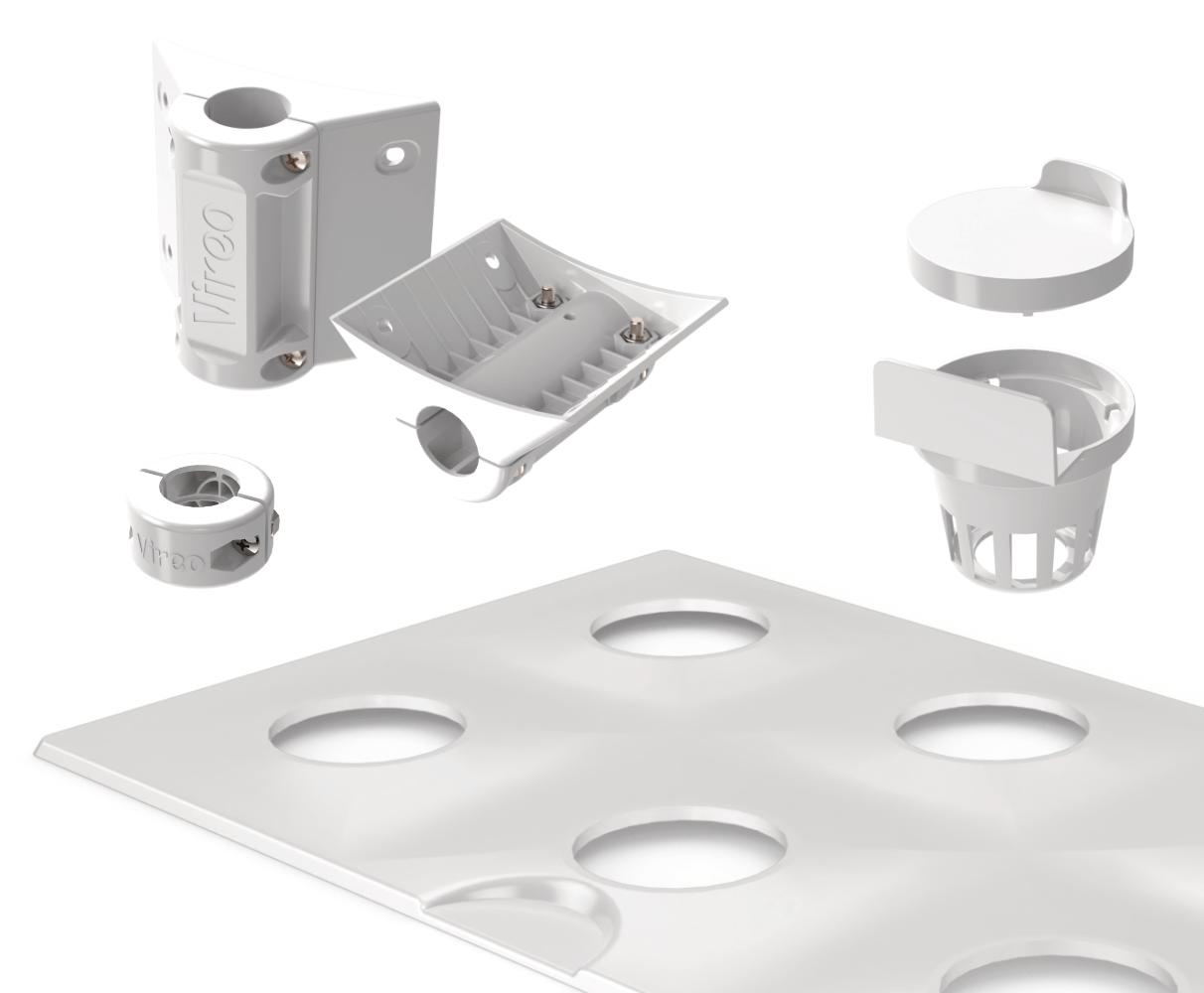

To ensure a competitive production price, the finished product consists of six injection-molded plastic parts.

Previously machined flat, the pot supports were completely redesigned for injection molding to optimize their mechanical properties while reducing manufacturing costs.

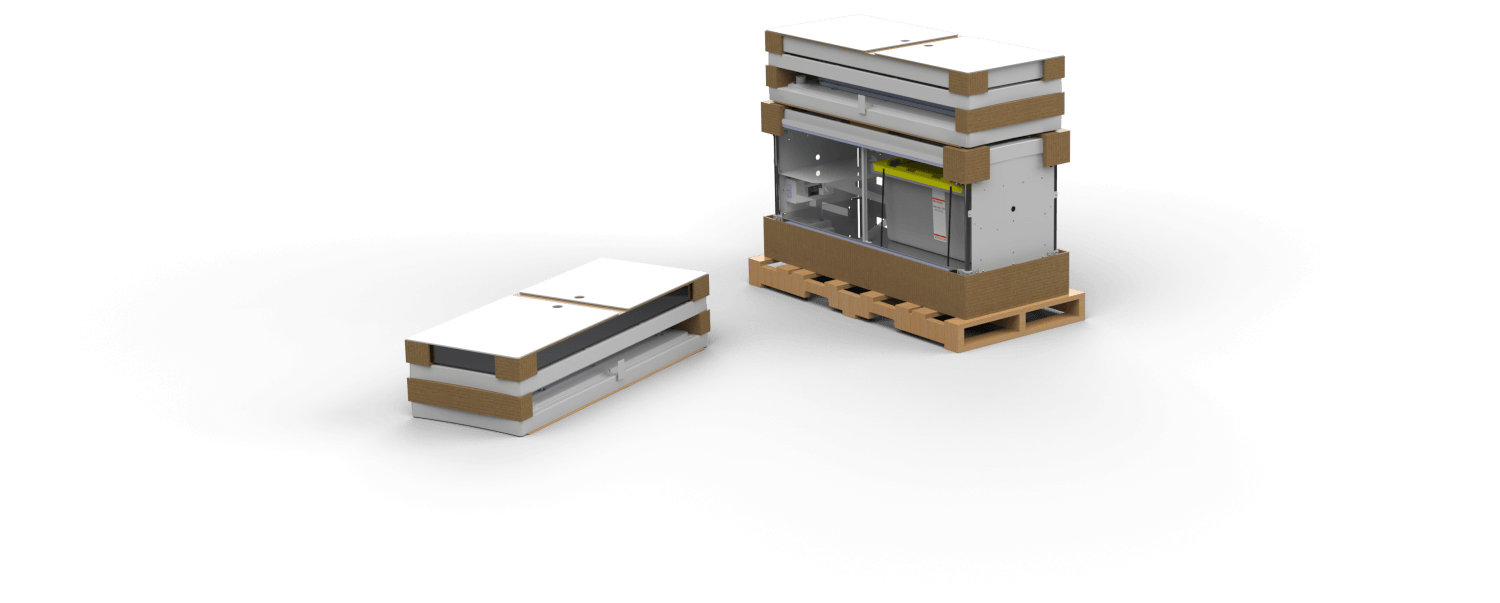

Packaging design

Optimize space

Product development would be incomplete if packaging and transportation were overlooked. That’s why the packaging steps were carefully designed to optimize space and weight while meeting the requirements related to the product assembly.

"Leaving nothing to chance is saving work"

Manufacturing

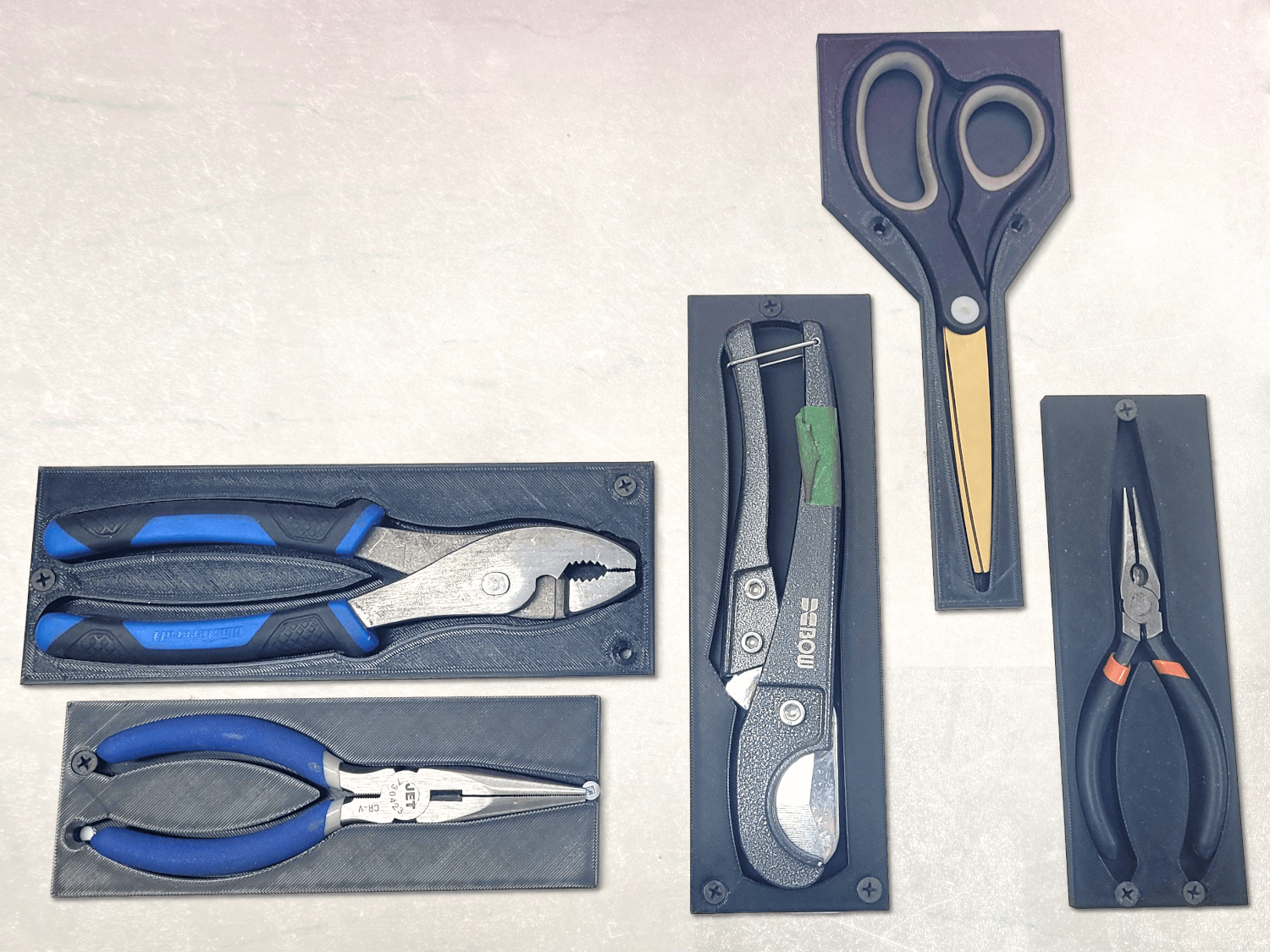

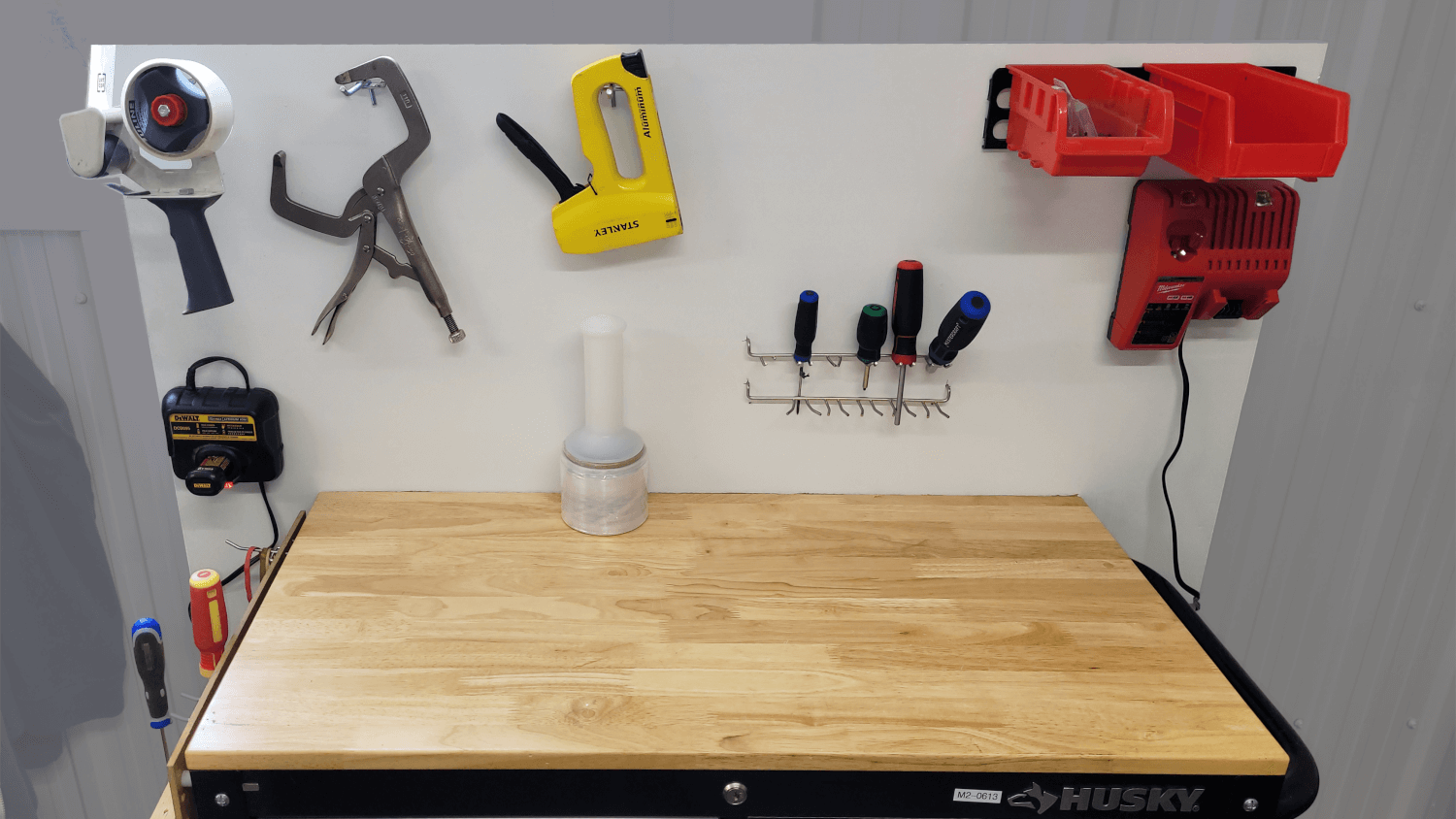

Ergonomics and productivity

At Innovation M2, employee well-being is a priority, as it plays a key role in retaining expertise. With this in mind, before launching production, we developed tools aimed at maximizing production flow and improving workstation ergonomics, inspired by the 5S methodology. This approach also adds value for the customer, who benefits from a product assembled efficiently in a secure environment.

La méthode de rangement, connue pour son efficacité à se concentrer sur l’essentiel, permet d’éviter la perte d’outils et d'optimiser l'organisation du travail.

From Concept to Market

Go-to-market

Participating in all stages of the go-to-market process offers several advantages. It allows for quickly intercepting potential errors and identifying improvements to be made to the product. Additionally, this approach facilitates decision-making in the short, medium, and long term, enabling optimal product evolution.

Quality control tools have been implemented to ensure that every product delivered is free of defects.

Go/No-Go checklists have been integrated to ensure rigorous control at every stage of the process.

Testimonial

- Luc Goudreault,

CEO of Vireo

"At Vireo, we found in Innovation M2 much more than a supplier: a true strategic partner. Their availability, their exemplary dedication and their ability to listen to our needs played a decisive role in the creation of an innovative solution, perfectly adapted to our users. Thanks to their expertise and commitment, we are proud to offer a product that shines our vision, both here and internationally. Collaborating with a local company as inspiring as Innovation M2 is a privilege that I warmly recommend to any organization in search of excellence."